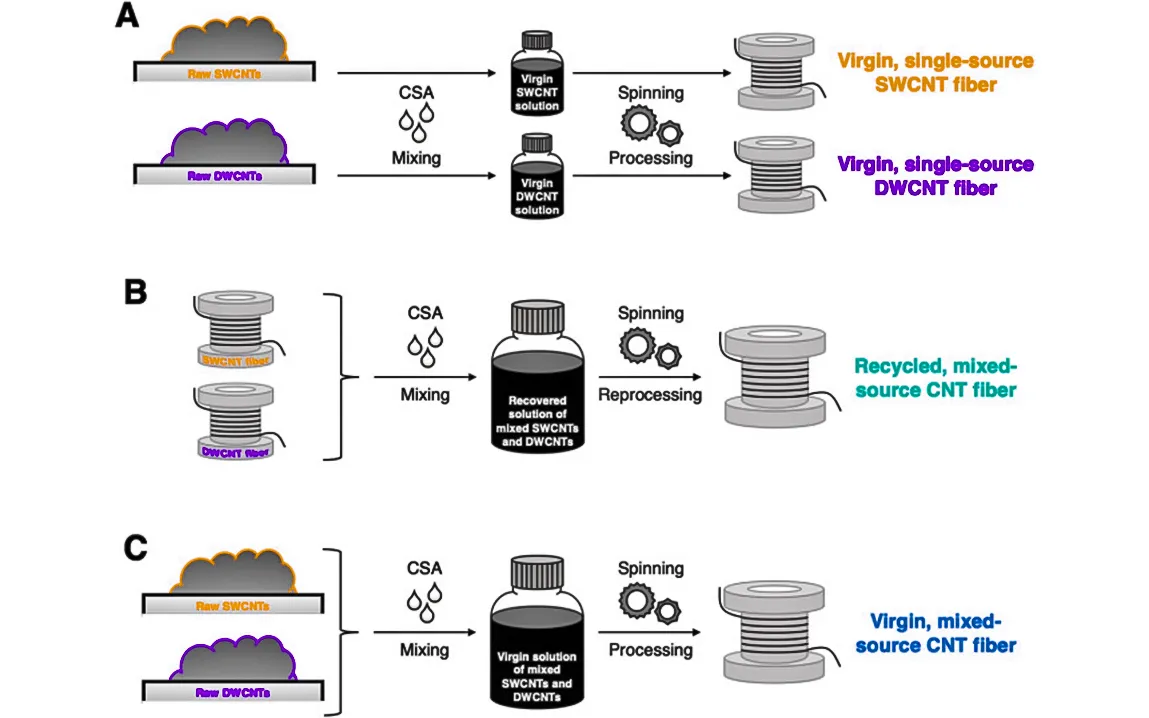

A new material in the works could change everything from manufacturing to medicine. Scientists at Rice University have developed the first fully recyclable carbon nanotube fibers-and they’re really strong and conductive. The tensile strength of these fibers is even stronger than that of traditional fibers such as Kevlar, and most importantly, it can be recycled without losing any core properties.

Carbon nanotubes are cylindrical molecules that have been admired for their remarkable mechanical properties, comprising carbon atoms arranged in a hexagonal pattern. However, until recently, their high cost and complicated methods of making them barred them from industrial use. The breakthrough at Rice University tackles these challenges with the development of a way to fabricate CNT fibers, which are not only stronger than materials such as Kevlar but also can be fully recycled.

Recyclable development of CNT fibers will, therefore, have wide ramifications in aerospace and automotive manufacturing. In aerospace, where the use of lighter and stronger materials is an important factor, CNT fibers could replace traditional components, reducing weight without sacrificing structural integrity. This may also lead to fuel-efficient aircraft and a reduction in carbon emissions. CNT fibers will be used in the manufacture of stronger and lighter parts in vehicles, improving fuel efficiency while enhancing safety. Their strength for resisting extreme environmental and physical conditions makes them suitable also for construction applications in advanced material systems for bridges, buildings, and other structures.

One of the most exciting properties of the CNT fibers developed at Rice University is their very high electrical conductivity. These fibers have the capacity to conduct electricity at a magnitude very close to that of copper, and their potential applications in the fields of electronics and energy storage are highly viable. Furthermore, the associated manufacturing process will ensure that such nanotubes are long, highly crystalline, and free of impurities, increasing their conductivity. This makes the resultant fibers stronger and more conductive than any other in existence and applies to a wide range of applications, from consumer electronics, sensors, and medical devices.

Another significant advantage of the technology is environmental sustainability. Material recycling has been one of the major challenges for industries dealing with high-performance fibers. Traditional materials such as Kevlar and fiberglass are hard to recycle and often end up in landfills. Meanwhile, the CNT fibers developed at Rice University can be degraded and reused without losing their structural properties, making them a far more sustainable option. This would help reduce waste but also limit the need for new raw materials, contributing to the circular economy.

Another reason this technology has been promising for scaling up and reaching more industries is scalability. The researchers have designed such a process to make these fibers that can be easily integrated into existing manufacturing systems. Therefore, industries should be able to adopt the technology without expensive retooling or significant changes in their production lines. Indeed, the authors further note that the production process of the fibers could be optimized even more by minimizing carbon emissions, adding another layer to the environmental benefits.

The potential applications of recyclable carbon nanotube fibers are immense, from more efficient electronics to lighter and stronger construction materials. This technology is likely to play a significant role in the reduction of environmental impacts from manufacturing and in expanding the performance envelope for materials.

Overall, fully recyclable carbon nanotube fibers mark an important advance in the development of material science. Having impressive strength, conductivity, and further sustainability, this kind of fiber can change the aerospace to electronics industries and add to the creation of a sustainable future. While much research and production methodologies are still in their development stages, the large-scale application of CNT fibers might just be around the corner, marking a significant step toward more eco-friendly, high-performance manufacturing solutions.