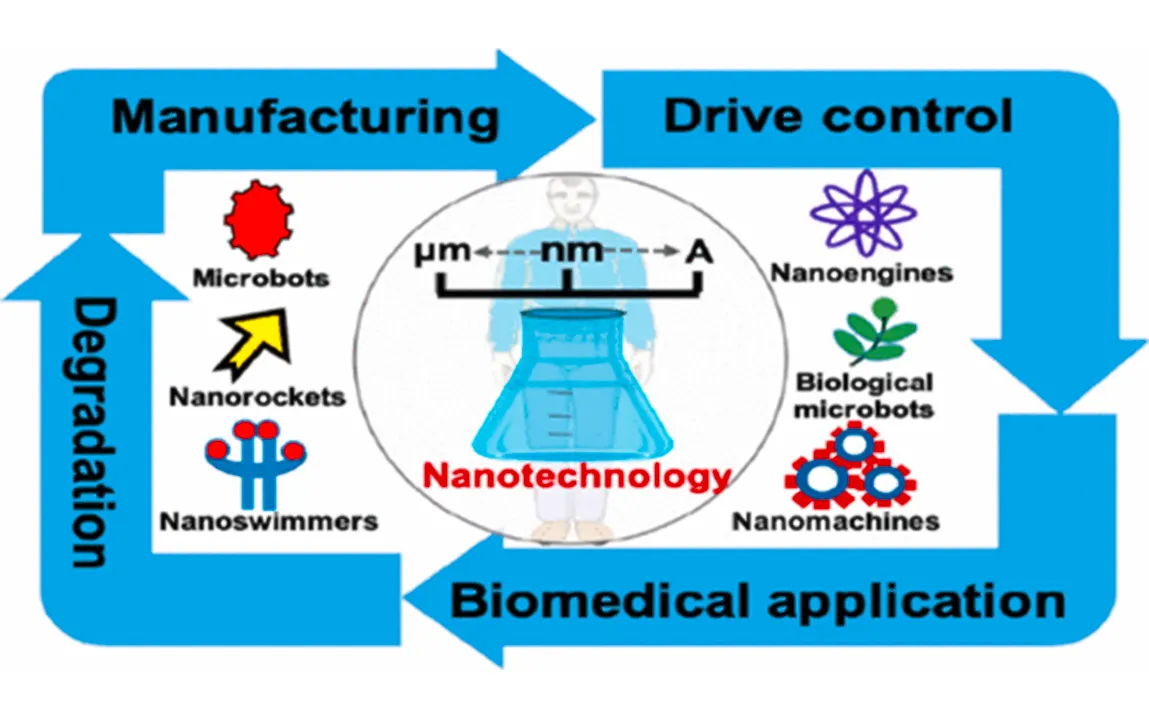

Recent breakthroughs in the field of microrobotics are paving the way for a new generation of tiny, highly adaptable machines that could dramatically impact both healthcare and industrial manufacturing. These microrobots, no larger than a grain of sand, can perform feats that, until recently, were considered impossible, given their extremely small size and the complexity of their work. Probably the most promising inventions are DNA-linked microrobots: modular, mobile devices that derive their programmability, assembly, and operation from biological molecules, totally opening up new avenues for their use in medicine, manufacturing, and beyond.

Modular Micro-Robots on the Rise

While the idea of modular microrobots is not new, which are assembled in a multipart form that can be remade into different configurations to suit the particularities of one or another type of task, recent developments in materials science and techniques for microfabrication have made these robots far more versatile and effective than their predecessors. Nowadays, scientists integrate advanced functionalities into such microrobots with accuracy for precise tasks where conventional robots cannot access them.

Central to this is the use of DNA in linking and programming these microrobots. With its unparalleled capability to store enormous information in minimal space, DNA has become an ideal agent in dictating the behavior of the microscopic robot. By using DNA molecules as “programming” tools, scientists are able to drive self-assembly and motion in microrobots with unprecedented precision. They are designed to be modular, such that they can be put together in different ways depending on the mission. Such versatility extends their functionality to targeted drug delivery in medicine and into precise component assembly in manufacturing.

Transforming Medicine: Precision Surgery and Drug Delivery

The most promising application of DNA-linked microrobots has to be within medicine. Such robots could entirely break new grounds for surgery and drug delivery, affording wide-ranging operations that are extremely accurate and minimally invasive. For instance, in cancer treatments, these microrobots could be programmed to deliver chemotherapy drugs directly to the tumor cells, causing the least possible harm to the healthy tissues surrounding them. They may also perform complex surgeries on difficult-to-reach parts of the body, such as inside blood vessels or organs.

The application of microrobots for medical use is quite exciting, as these could be controlled from the outside and thus allow highly focused treatments by health care providers in real time. Moreover, DNA-linked robots can also be engineered to “sense” their environment through chemical signals or other stimuli within the body. It follows, therefore, that this may enable the robots to make decisions in real time on when and how to deliver their therapeutic payload for optimized treatment outcomes.

The concept is also promising for non-invasive diagnostics: for example, DNA-linked microrobots could be programmed to search for specific biomarkers in the body and return diagnostic data to inform doctors in early disease detection and personalized treatment plans. The precision and adaptability of these robots make them invaluable tools within the medical armamentarium and open up new avenues for both preventive and corrective healthcare.

Redefining Manufacturing: Micro-assembly and Environmental Monitoring

Beyond healthcare, the potential of DNA-linked microrobots to transform manufacturing processes is enormous. Their size and agility let them execute intricate tasks that are simply impossible for larger robots or human workers. In the electronics industry, for example, microrobots could be used to assemble the tiny, delicate components of microchips and other advanced technologies. Their modular nature means they can work collaboratively, forming swarms that carry out complex tasks with speed and accuracy.

Of particular interest to manufacturers is the potential to use such robots in the assembly of small-scale components. Their ability to manipulate at the micro and nanoscales will enable the design of extremely precise devices and systems that can also be highly energy-efficient. Besides manufacturing, such robots can be applied to various environmental tasks, such as cleaning contamination or monitoring environmental conditions. They can also be used for monitoring harmful chemicals or pollutants in water or air in order to give timely data on and actuate agents to clean it or neutralize the pollutant.

Modularity enables them to cooperate in groups in such a way that, depending on task demands, the topology will self-configure dynamically. For instance, a cluster of the microrobots would act as a distributed entity where all individual robots perform specific operations, including manipulation of parts, locomotion, and even providing haptic feedback to human users. This cooperation at such a degree of miniaturization is another huge leap toward enabling advanced, fast, and more flexible fabrication.

Sustainability and the Future of Robotics

Like any other new technology, their environmental impact has to be taken into consideration, which these microrobots will bring with them. Thankfully, researchers are increasingly focused on ensuring these robots are not only functional but also sustainable. Many of the newly developed designs of microrobots are made of friendly materials to the environment, while the energy consumed by them is at a minimal level, mostly drawing their energy from the environment, such as solar power. This sustainability factor meets the growing emphasis on green technology in both medical and industrial sectors.

Moreover, the DNA-based nature of such robots opens perspectives toward bio-inspired design: self-assembly and even self-repair become possible, like in biological cells. These will be very efficient and self-sustaining systems, with very limited human intervention. As these technologies continue to evolve, they may significantly contribute to solving some of the most pressing global challenges, which range from the treatment of diseases to cleaning up the environment.

Challenges and Future Prospects

While these possibilities sound so promising, there are still some challenges to be met, such as miniaturizing robotic components, energy harvesting, and precision in DNA-based programming-all issues currently under laborious activity by researchers. Besides, ethical issues in using autonomous robots in sensitive areas, like the human body, will have to be carefully considered.

However, the future of DNA-linked microrobots, both for medical and manufacturing purposes, would be bright. It is very well expected that as the technology advances, such tiny machines will form the backbone of several industries, providing unprecedented levels of precision, adaptability, and efficiency. From small-scale surgery operations to highly targeted treatments or shifting manufacturing processes, the potential of such micro, modular, mobile robots is huge-very exciting possibilities toward a more efficient and sustainable future.